Productivity and efficiency are two words people often use interchangeably.

But, do these words mean the same thing?

When people say you should be more productive, are they saying you should be more efficient, and vice versa?

Well, not quite.

Even though both words have similarities, they have distinctly different meanings.

Just because you’re productive doesn’t mean you’re efficient and vice versa.

So, without maximizing both, you could end up stopping your business from achieving its highest potential.

Today, we’ll discuss everything you need to know about both terms, including their definition, examples, best practices, and ideas to maximize them.

Let’s start with the basics.

What is productivity?

The term “productivity” is relative to production. It measures the total output produced in a period (e.g., “I built two houses this month”).

Productivity can be absolute, as it refers to the number of outputs you produce, regardless of the production of others.

But it can also be relative.

If you can produce three cakes in a working day, but a competitor produces four in the same period, we can say that your competitor is more productive.

In other words, productivity measures the performance of your production in relation to any factor of production, not just time.

In economics, “factors of production” refers to the input required to produce a certain good or service, including:

- Labor productivity: Calculates production per labor hour (e.g., “I can bake three cakes every hour worked”).

- Capital productivity: Determines your overall productivity based on how much capital you use to produce an output (e.g., “To produce 40 cakes, I need to use the oven for 16 hours, which costs me $40”).

- Material productivity: Measures your productivity based on material units needed (e.g., “To produce a cake, I need 30 material units”)

- Multifactor productivity: Indicates your productivity by combining all other factors.

The most commonly used, though, are labor and capital.

For example, let’s imagine that you own a manufacturing company that produces cars.

You could measure the productivity of your employees by comparing the number of cars produced per labor hour.

If an employee produces three cars per labor hour and another produces just one, the first is more productive.

You could also compare your employee’s productivity against “dollar inputs” (i.e., how much it costs to produce a unit).

If an employee can produce, say, a car per dollar input, and the other produces 0.5 cars, the first one is more productive in terms of economic productivity.

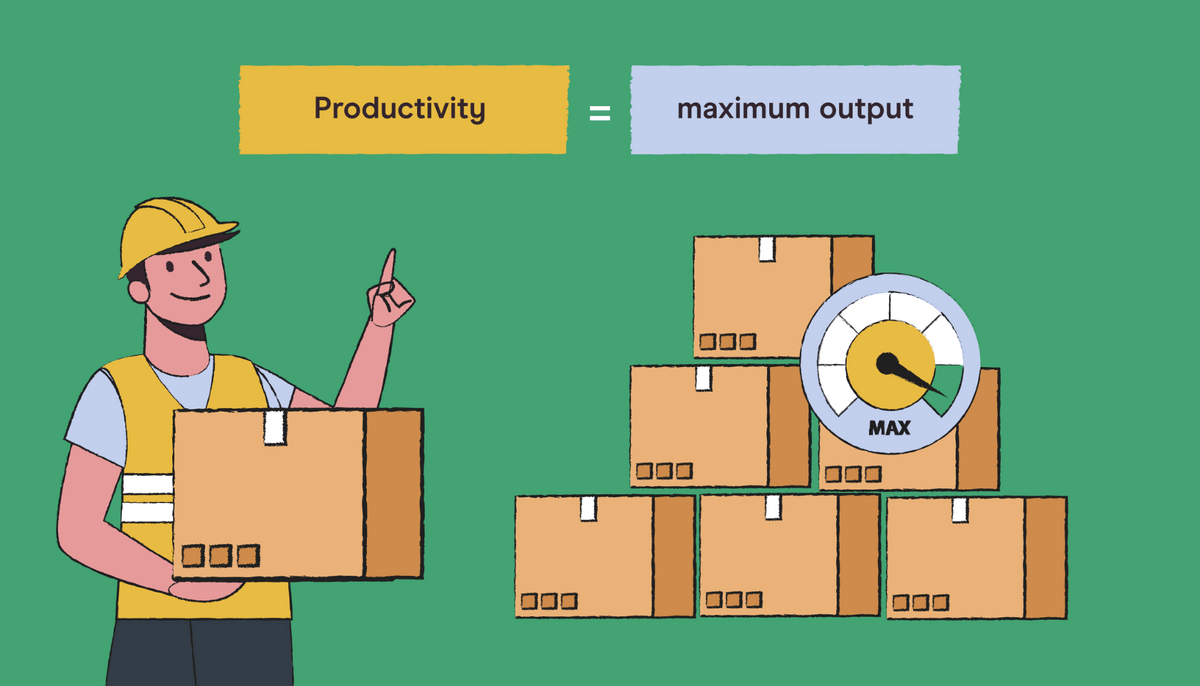

Productivity is all about maximizing your total output.

You need to define what success really means for you and then use that metric to measure your team’s productivity.

Why should you measure productivity in your organization?

First, your organization’s productivity dictates your capacity.

If you haven’t measured your productivity, you don’t really know what your maximum capacity is, and you might end up making a fatal deal that could hurt your business dramatically.

Following the manufacturing example, imagine you take on a new client that wants 1,000 cars per year, but you can only produce 500.

It won’t end well for you or the client when you belatedly discover you’re not going to be able to hit the target.

Productivity measurement is crucial because it tells you how much work you can take.

Second, you can’t grow what you don’t measure.

You see, teams aren’t as productive as you may think.

In a recent survey, roughly 8 out of 10 employees confessed they weren’t productive “throughout the whole working day.”

The same study found that, on average, employees are productive for less than three hours per day.

What does this mean for you?

If you don’t measure your organization’s productivity, you can’t pinpoint where the problems are and you’ll probably settle for less than your true capacity.

But, by measuring productivity across employees and time, you can pinpoint bottlenecks and other issues that are killing productivity and then work to remove these things.

What is efficiency?

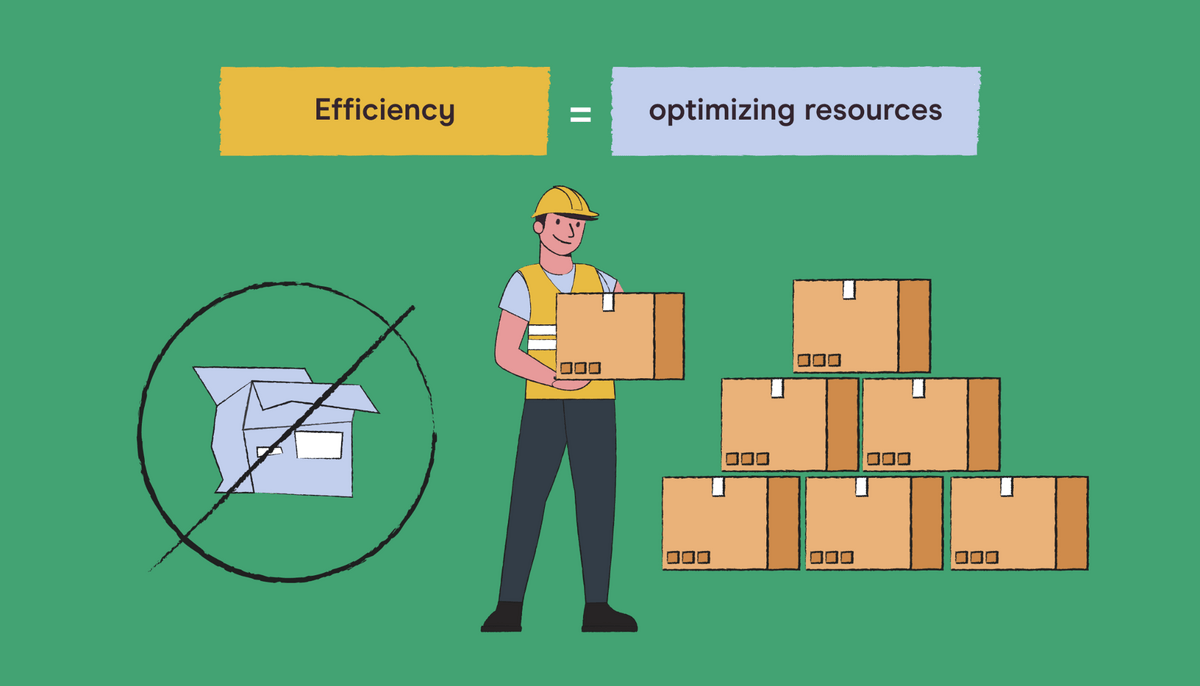

Efficiency is a metric that measures the correct management and utilization of resources to produce a specific output.

Efficiency determines whether you’re using your available resources in the most effective, non-wasteful way.

Efficiency is a comparative metric.

To know whether you’re efficient, you need to compare your current performance against benchmarks and standards.

These standards can be established by different factors, including:

- Competition: How efficient are your competitors? (e.g., “My top competitor is producing each smartphone for just $100”).

- Past performance: How efficient have you been in the past? (e.g., “Last year, our company was able to build a new desk in just two hours, using nine material units”).

- Industry: How efficient are similar businesses in your industry(e.g., “The average winery can produce a bottle of wine every three seconds”).

Let’s say that you own a lemonade stand, and it costs you $1 to produce a glass of lemonade.

But all of a sudden, your neighbor decides to start a lemonade business too. The thing is, he can produce lemonades for just 50 cents.

In this scenario, your neighbor is more efficient than you — he can produce the same quantity of units with fewer resources.

There are different types of efficiency, and you need to determine which are most relevant for your business.

The most popular efficiency types include:

- Allocative efficiency: Measures the efficiency of distributing your products and services in relation to customer preferences.

- Productive efficiency: Determines how efficient you are in relation to producing the maximum outputs with the least amount of inputs and operating expenses.

- Dynamic efficiency: Describes the progressive efficiency of your organization over time.

- Social efficiency: Measures an organization’s efficiency in proportion to private and social costs involved in a decision.

- X-efficiency: Determines the efficiency in which you can produce the maximum output in relation to management incentives.

Why should you measure efficiency in your organization?

Measuring your efficiency will help you identify areas of waste and revenue leaks in your organization, and develop ideas to fix them.

By identifying where you’re wasting most of your resources, you can design and implement initiatives to improve those areas and processes.

Following the lemonade stand example, if you find out that cutting lemons is your least efficient process, you could buy an automatic lemon slicing machine. This way, you could save time and become more efficient.

You might also discover that your provider is overpricing lemons.

By renegotiating costs or looking for a different provider, you could reduce costs and also become more efficient.

Without measuring your current efficiency, though, figuring out those things wouldn’t be possible.

Efficiency measuring will reveal opportunity gaps you can fill, as well as potential threats.

You should adopt a continuous improvement culture for your business and constantly monitor your least efficient processes.Otherwise, growing and scaling your business will be much harder.

Productivity vs. efficiency: the main differences

Now that you understand the basics of productivity and efficiency, let’s dig a bit deeper into the major differences between both terms.

To better understand these differences, let’s use an example.

You’re the owner of a woodworking shop and want to know how productive and efficient your employees are.

So, one day, you analyze the output of two workers.

To do it, you use the following benchmarks:

- Average number of material units to build a desk: 10 units

- Average time to build a desk: one hour

Employee A built 10 desks in 12 hours and used 150 material units.

Employee B built 5 desks in 3 hours and used 40 material units.

In this scenario, employee A was more productive because they produced more desks during the day.

But they were less efficient because it took them more time and materials to build each desk (an average of 1.2 hours and 15 material units per desk).

On the other hand, Employee B was more efficient. They used fewer resources to build each desk (0.6 hours and 8 material units per desk).

But, they were less productive because they produced fewer desks that day.

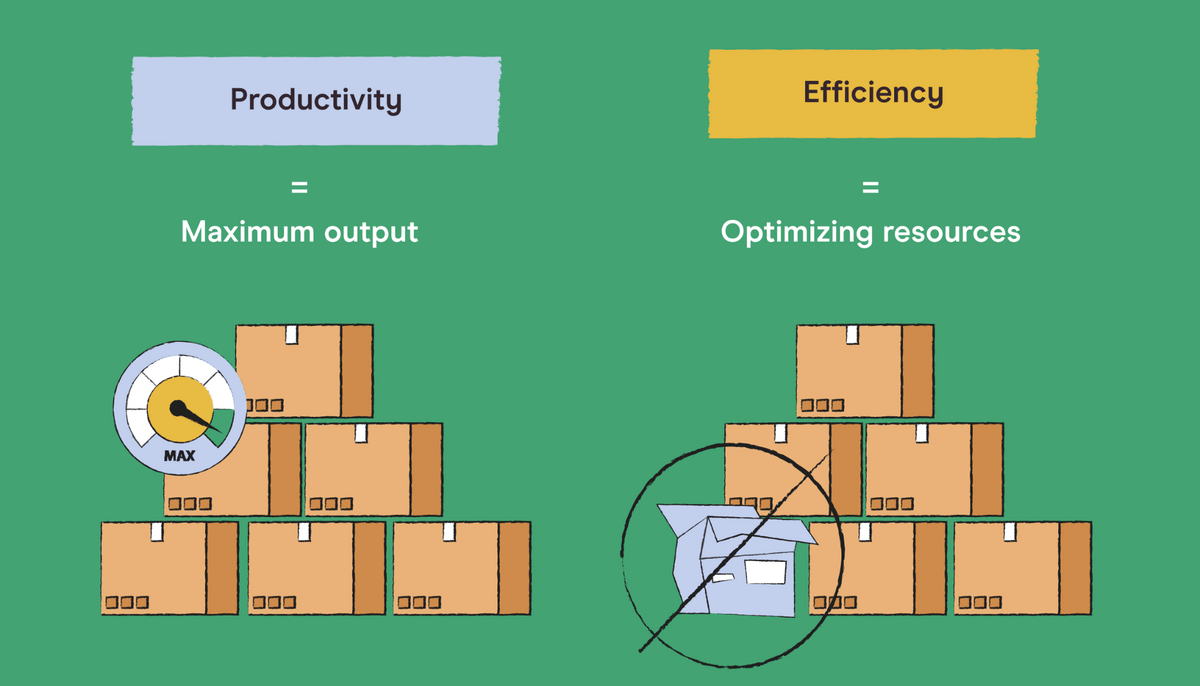

In short, the main difference between productivity and efficiency lies in the objective of each.

Productivity maximizes outputs, whereas efficiency aims to optimize resources.

Three tips to maximize your productivity and efficiency

At this point, you already understand the main differences between productivity and efficiency. Now the question becomes: How can you maximize both?

Here are three helpful tips:

1. Tap into automations

Manual work is one of the top productivity killers.

Think about the wine industry.

Back in the early 1900s, when wineries relied on manual-powered labelers, overall productivity depended on the operator’s speed. If the operators were quick enough, they could label around 10 bottles per minute (or 600 bottles per hour).

Nowadays, a fully automated labeler machine can label around 150 to 200 bottles per minute (about 9,000 to 12,000 bottles per hour).

That’s 20X more production.

By automating the labeling process, wineries now need fewer employees and resources to produce even more bottles.

So, automation increases not only your productivity but also your efficiency. It helps you reduce costs and optimize resources.

And the wine industry isn’t an isolated case.

Studies reveal that 30% of today’s most important tasks can be completely automated in 6 out of 10 industries.

With the help of technology and AI, you can automate repetitive tasks and processes, maximizing both productivity and efficiency.

The best part?

You don’t need deep pockets to tap into this trend.

Modern project management software can automate most of the day-to-day operations of most businesses, including reporting, communication, collaboration, and more.

2. Improve your talent selection and training

Many businesses are unproductive and inefficient. And it’s often because of bad processes, a lack of resources, or obsolete technology.

It’s because they don’t have the right talent.

Maybe their teams aren’t working hard enough. Perhaps they haven’t adapted to remote work. Or maybe they simply don’t have the required skills to complete the tasks.

Remember, a chain is only as strong as its weakest link.

In the same way, an organization is as strong as its weakest member.

By improving your talent selection and training processes, your team will be better equipped to solve issues faster, work more efficiently, and produce more.

For example, you could adopt a collaborative knowledge management system where members with specialized knowledge help one another.

You could also train your HR team and develop a more solid selection process.

It’s even possible to implement gamification to create a more enjoyable work environment.

The point is that you should look for ways to develop a more cohesive team capable of doing the work in the most efficient way possible and meeting your productivity standards.

3. Adopt business process reengineering

As your organization grows, so does its complexity.

The more complexity you have in your processes and operations, the more productivity and efficiency barriers you’ll face.

Here’s where business process reengineering (BPR) comes into play.

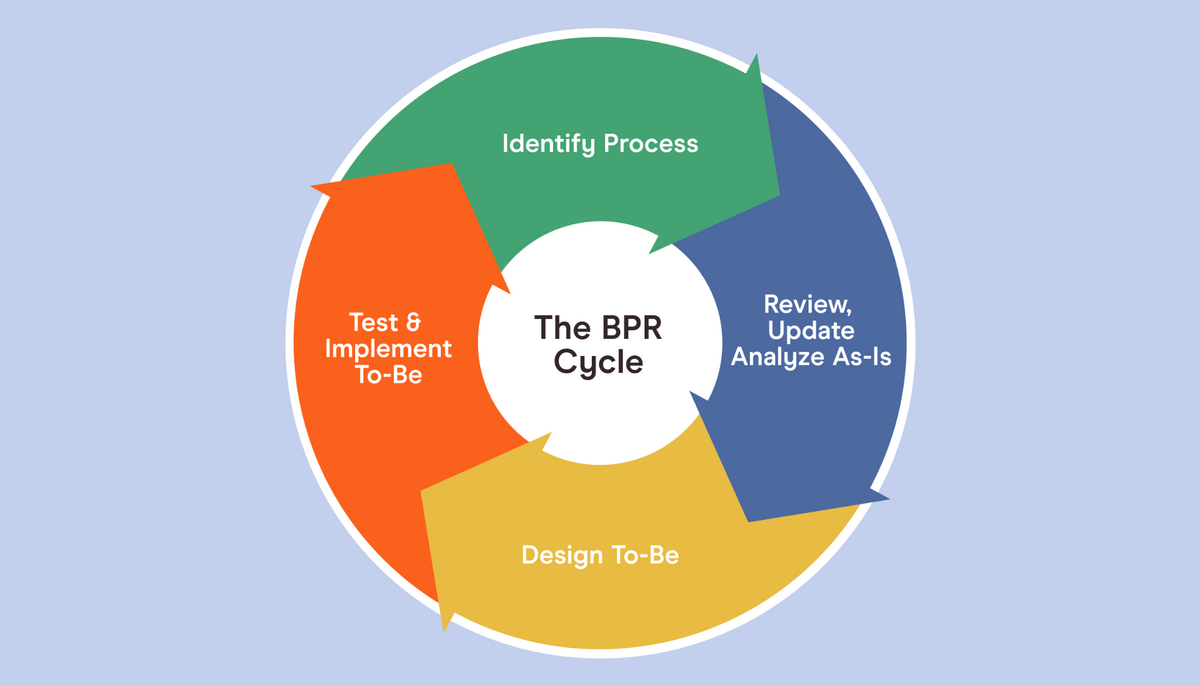

Business process reengineering is the discipline of breaking down your processes into pieces to find potential opportunity gaps.

The idea is that you should identify processes that aren’t meeting your standards and redesign those processes until you achieve the desired results. Thus, this is a continuous task.

This methodology consists of five main steps:

- Identify process: Identify the process you want to redesign.

- Review, update, and analyze: Identify all the elements that make up your process and spot potential problems or bottlenecks.

- Design a new process: Remove and/or add steps in your process or start from scratch, if needed.

- Test and implement new process: Implement your new process and analyze results.

- Repeat: Repeat the cycle until you achieve the desired results.

BPR goes hand in hand with continuous improvement and can help you maximize both productivity and efficiency.

The bottom line?

Productivity without efficiency can increase your costs and reduce the quality of your products and services.

On the other hand, efficiency without productivity might hurt your ability to scale and grow in highly competitive industries.

Hopefully, you now have a better understanding of the differences between these two terms and some ideas to get the best of both worlds.

Check out our course on How to Manage People to learn more skills that can help you and your team become more productive and efficient at work.

Pareto Labs offers engaging on demand courses in business fundamentals. Built to help you elevate your game at work, our courses distill complex business topics — like how to read financial statements, how to manage people, or even how to value a business — into digestible lessons. No business background required. Our library of 200+ lessons will teach you exactly what you need to know to use it at work tomorrow. Sign up for a free trial today to start watching.